PET Mould India specializes in manufacturing high-performance Blow Moulds and HDPE Blow Moulds engineered for precision, consistent wall thickness, and long-lasting durability. Our moulds support efficient bottle and container production across FMCG, pharmaceutical, food, agro, and industrial packaging sectors.

Uniform wall distribution and consistent container shape across all cavities.

Specialized blow moulds for HDPE bottles, jerry cans, and containers.

Compatible with single- and multi-cavity blow moulding systems.

Manufactured from high-grade tool steel for long mould life and stability.

PET Mould India designs and manufactures Blow Moulds and HDPE Blow Moulds that meet the demanding requirements of modern plastic packaging lines. Our moulds are engineered to deliver consistent wall thickness, precise neck finishes, and excellent surface quality even at high production speeds.

From small bottles to large-volume containers, our blow moulds are suitable for producing round, square, oval, and custom-shaped products. We also offer specialised solutions for handle containers, jerry cans, dairy bottles, and industrial packaging applications.

With optimized cooling channels, interchangeable inserts, and corrosion- resistant coatings, our moulds help manufacturers reduce cycle time, minimize downtime, and achieve reliable long-term performance.

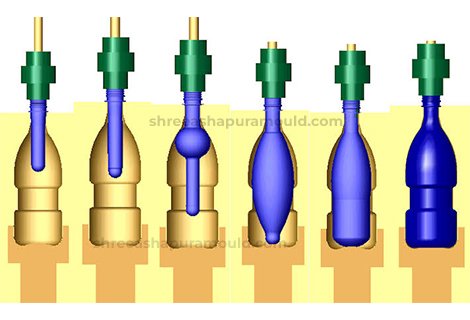

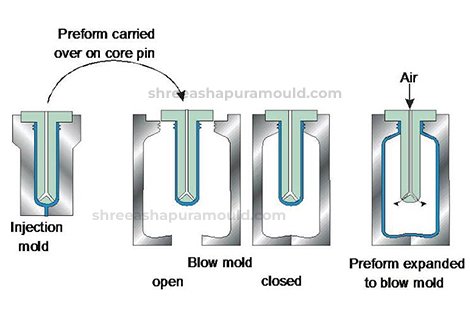

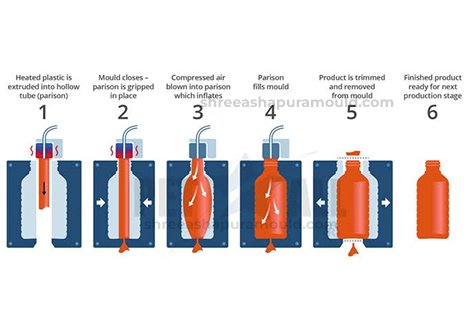

Blow moulds are used to manufacture hollow plastic products, while HDPE blow moulds are specifically designed for High-Density Polyethylene containers used in chemicals, dairy, and lubricants.

PET Mould India designs blow moulds compatible with HDPE, PET, LDPE, and PP based on your application requirements.

Yes, we specialize in custom blow moulds including handle bottles, jerry cans, and brand-specific container designs.

Our moulds are compatible with extrusion blow moulding, injection blow moulding, and stretch blow moulding machines from leading brands.

Yes, PET Mould India offers mould trials, sample testing, and on-site support to ensure optimal performance on your production line.

Copyright © 2025 Pet Mould India